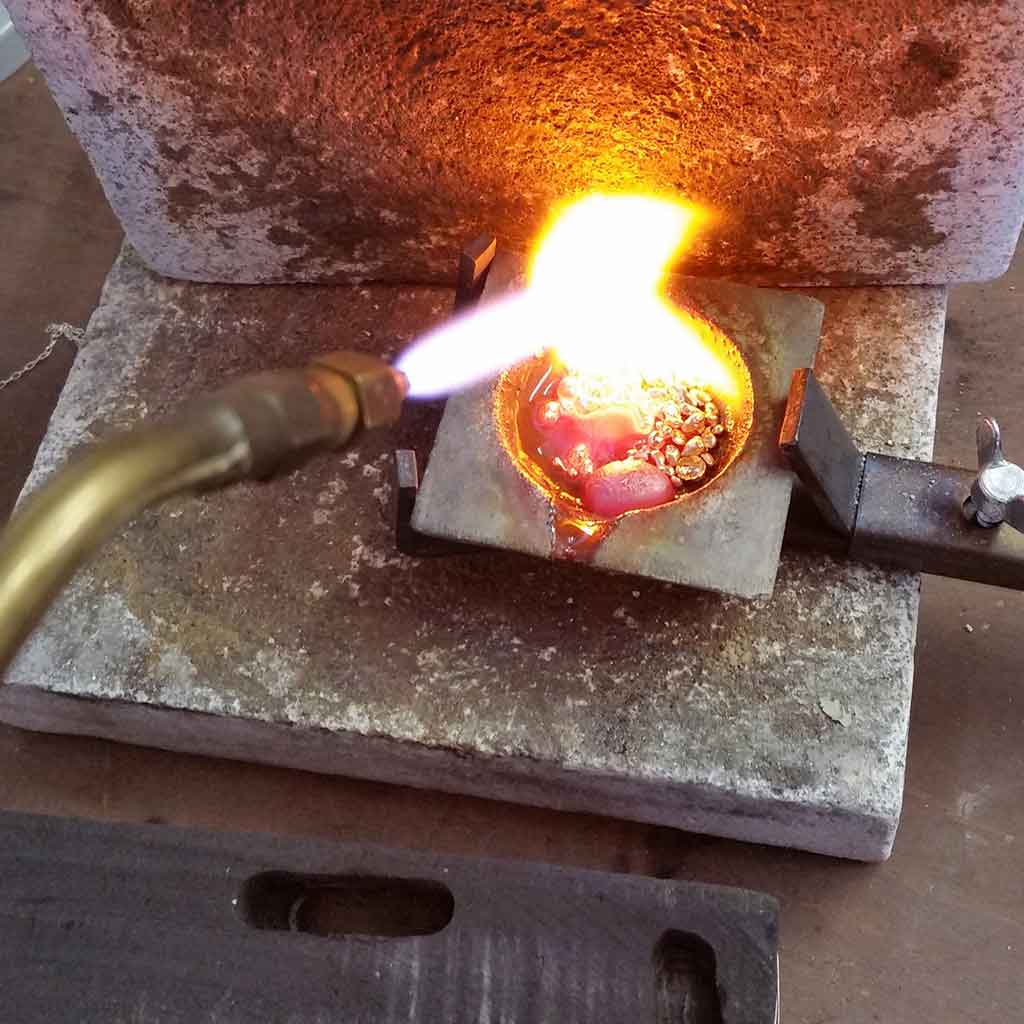

Melting Metal

First, as part of ethical jewellery practice and commitment to the craft of goldsmithing, Amanda hand alloys her own precious metals.

Colour, karat and toneAmanda alloys her own metals, which gives you both full control and choice in how the piece will look, as well as ensuring the provenance and responsibility of her materials. For instance, she can match the colour of a wedding band to an existing engagement ring, or choose something to compliment one's skin tone or gemstone. If available, Amanda can repurpose gold from an heirloom piece of jewellery and reuse it to make your new design, giving a treasured piece a new life. Here is the range of precious metals available, including Fairmined and Fairtrade Gold:

Each metal is an alloy, bringing together a combination of metal elements in different ratios, such as gold, silver and copper. For each piece of jewellery, Amanda carefully weighs out each of these metals, in their pure granular form, and melts them into a single ingot to work with from scratch.

Hand forming& texture

As a goldsmith, Amanda uses traditional tools to shape the metal nugget into its final form by hand, before applying the final textures and finish.

Hand fabricationThis is where the real work happens. From the alloyed ingot, Amanda uses traditional methods to hand-fabricate the metal into its final form. which produces a look, feel and finish that is unique to each piece.

Applied finishes & engravingAmanda specializes in creating a variety of hand-applied surface textures, using different hammers and specialist tools. Different finishes can create interesting visual effects that might highlight a particular surface or metal colour. Finishes you can find her work include polished, satin matte, hand filed, engraved lines or patterns, and round or linear hammered textures.

Setting the stones

Amanda uses responsibly sourced gemstones where they are often traceable back to the mine or country of origin. Each stone is individually hand selected and set into the finished piece.

Quality & ethicsThe provenance and quality of the materials that Amanda uses are incredibly important. Every piece of jewellery has its own story, and so should the elements used in making it. Amanda specialises in responsibly sourced diamonds, both natural and lab-grown. She also works with traceable coloured gemstones, including rubies, sapphires, emeralds and opals to less well-known stones, such as Imperial Diopside and spinel. If you are looking for something in particular, please do not hesitate to ask.

Gemstone settingAll gemstones are set by hand, from the large central stones in Amanda's engagement rings, to the delicate and highly technical work needed to micropave set the tiniest of diamonds.

Finishing Touches

Amanda's jewellery is finally hallmarked and hand polished.

Hallmarked in LondonOn completion, each piece of jewellery is sent to the London Assay Office for hallmarking. This hallmark comprises marks confirming that Amanda is the maker (with her own ALH stamp), the metal, metal fineness (%), it was tested in London, and the year it was made. If it is made of Fairtrade metals, it will also have the Fairtrade mark.

The final polishOnce the piece of jewellery has been returned to my studio from the Assay Office, Amanda cleans and hand polishes it before placing it in a beautiful box, ready to be collected and worn!